Bergbaumaschinerie arbeitet in anspruchsvollen Umgebungen mit hohem StaubniveauAnwesend starker Aufprallbelastung und Exposition gegenüber korrosiven Substanzen. Bei herkömmlichen Lagern treten häufig die Leistungsverschlechterung aufgrund von Fettkontamination, Versiegelungsverschleiß und damit verbundenen Problemen auf. Diese Probleme führen zu häufigen Ausfallzeiten für Geräte, was sich auf die Gesamtproduktivität auswirkt. Selbsthilfslager bieten durch die Verwendung von selbstschmierenden Materialien und spezifischen strukturellen Konstruktionen einen verbesserten Verschleiß- und Korrosionsbeständigkeit sowie verringerte Wartungsanforderungen. Diese Eigenschaften haben zu ihrem zunehmenden Einsatz in Bergbaugerätesystemen geführt.

1. Anwendungsbeispiele in Bergbaugeräten

1,1 Schleier -Schneideinheitslager

-

Trommelschacht schneiden : Die Scherer begegnen intermittierende Peakvibrationsbelastungen über 100 MPa, und Kohle -Gangstaub (MOHS -Härte 4–5) trägt zu einem beschleunigten Abrieb bei. In einer Shanxi-Kohlemine wurden mit Stahl mit Stahl gezwungenes Kupferpulver mit einer Wolfram-Carbid-Beschichtung (WC) aufgetragen. Mit einer Schnitttiefe von 1 Meter wurde der Lagerverschleiß von 0,12 mm nach 800 Stunden Betrieb gemessen - etwa die doppelte Lebensdauer herkömmlicher Lager, wobei die jährliche Wartungsfrequenz erheblich reduziert wurde.

-

Wickelarmverbindungen : Higromium-Gusseisen-Selbstschmierrichter werden an Gelenkpunkten verwendet, die sich wechselnden Aufprallkräften gegenübersehen. Feldtests durch die Shenhua -Gruppe ergaben eine dynamische Belastungskapazität von 150 kN und eine Reduzierung der mechanischen Versagenereignisse um 75%.

1.2 Mine Förderer Roller -Stützlager

-

Unterirdische Fördererwalzen : Die Exposition gegenüber Feuchtigkeit und feinem Staub führte einen australischen Eisenerzoperation an, um selbstschmierende Lager aus 316L Edelstahl mit MOS₂ (Molybdän-Disulfid) zu übernehmen. In einer Umgebung mit einer Staubkonzentration von 200 mg/m³ wechselte die Lagerersatzintervalle von 3 auf 18 Monate, wobei die Wartungskosten um 65%gesenkt wurden.

-

Toleranz von Fehlausrichtungen : Selbstausrichtung kugelförmige Strukturen ermöglichen eine Fehlausrichtung von Gürtel von bis zu 5 °. Ein Fall aus einer südafrikanischen Goldmine ergab eine 40% ige Zunahme der Lebensdauer bei Rollenlagern mit dieser Funktion.

1,3 Lager in Brecherkomponenten

-

Hammerschlecher Rotorwellen : Ein deutscher Gerätehersteller, der einem Aufpralldruck von bis zu 80 MPa ausgesetzt ist, verabschiedete mehrschichtige Verbundlager (Stahlrücken, Kupferlegierungsschicht, PTFE-Oberfläche) zum Quetschen von Kalkstein. Diese Lager erreichten mehr als 6.000 Betriebsstunden ohne Jamming und zeigten ungefähr das Dreifache der Haltbarkeit traditioneller fettgeschmützter Lager.

-

Kieferbrecher -Schubschildplatten : In Systemen, die sich mit Erz, der Quarzsand enthält, (MOHS-Härte 7), zeigten Graphit-Kupper-Legierungslager einen minimalen Verschleiß (weniger als 0,5 mm pro Jahr). Eine Jiangxi -Kupfermine berichtete über einen Anstieg der Verschleißresistenz im Vergleich zu herkömmlichen Materialien.

1,4 Lager für Bergbau -LKW -Systeme

-

Suspensionslager : Selbsthungrische kugelförmige Plattenlager (z. B. SAE 12-Typ) bilden hochfrequente Vibrationen auf ungleichmäßigen Bergbaustraßen. Das Testen in einer Kupfermine in Chile zeigte eine verbesserte Resistenz gegen den Verschleiß, wodurch der jährliche Lagerersatz von viermal bis einmal verringert wurde.

-

Hydraulische Lenkführer : Lager aus Polyimid (PI) -Materialien hielten die Reibungskoeffizienten unter 0,1 bei Temperaturen von -30 ° C. Eine offene Mine in der inneren Mongolei beobachtete eine Abnahme von Kaltwettersystemausfällen um 80%.

2. Kriterien für wichtige Leistungsanforderungen und Auswahlkriterien

2.1 Verschleiß- und Schlagfestigkeit

Das Lagermaterial wird basierend auf Erzhärte und mechanischen Lasteigenschaften ausgewählt.

| Erztyp | Geeignete Lagermaterialien | Oberflächenhärte |

| Kohle (geringere Härte) | Kupferbasierte gesinterte PTFE-beschichtete Schichten | HB ≥ 150 |

| Metallerze (höhere Härte) | Mit WC beschichtete Stahl- oder Keramiktypen | HV ≥ 800 |

Laut ISO 4378-3 müssen die Lager für Bergbau-Nutzung mindestens 500.000 Zyklen der Aufprallbelastung standhalten, wobei während der Tests eine Lastschwankung von ± 40% gelegt werden.

2.2 Korrosionsschutz und Versiegelungsintegrität

-

Saure Wasserbedingungen (pH 3–5) : Lager aus Edelstahl 316L oder mit Nickelbeschichtung behandelt werden. Bei pH = 3-Lösungs-Tests zeigten nickelbezogene Oberflächen eine Korrosionsrate von 0,005 mm/Jahr, was signifikant übertriffte Kohlenstoffstahl, der bei etwa 0,2 mm/Jahr korrodierte.

-

Staubschutzanforderungen : Ein Dreifach-Seal-Ansatz (radiales Labyrinth, axiale PTFE-Lippenversiegelung und externe Staubbedeckung) blockiert 98% der Partikel> 0,1 mm. Diese Versiegelungskonfiguration wurde in einer Platinmine in Südafrika mit konstant positiven Ergebnissen getestet.

2.3 Betriebstemperaturbereich

Die Lager werden basierend auf thermischen Bedingungen ausgewählt:

| Betriebsumgebung | Temperaturbereich | Anwendbare Materialien |

| Untergrund (hohe Temperatur) | -20 ° C bis 150 ° C. | Graphit-Coper-Verbundwerkstoffe |

| Kaltes Klima (Oberfläche) | -50 ° C bis 80 ° C. | PI/PTFE -Verbundkombinationen |

| Hochtemperaturzonen (z. B. Brecher) | Sofortig bis zu 300 ° C | Siliziumnitrid -Keramiklager |

2.4 Lastkapazität und Geschwindigkeitskompatibilität

-

Niedriggeschwindigkeit, schwere Lastgebrauch (z. B. Brecher) : Kupferbasierte Sinterlager mit einer Oberflächenlastbewertung von ≥100 MPa, wodurch ASTM B438-Standards erfüllt werden.

-

Hochgeschwindigkeit, vibrierende Geräte (z. B. Bildschirme) : Lager mit Peek -Materialien ermöglichen lineare Geschwindigkeiten von bis zu 4 m/s und übertreffen typische Metallalternativen um 60%.

2.5 Kosten und Betriebseffizienz

Nach dem 2023 Globaler Bergbaulagermarktbericht , Selbsthilflager führen zu einer Gesamtbetriebskostenreduzierung von 20–30% im Vergleich zu herkömmlichen fett geschmierten Lösungen.

3. Branchenentwicklungen und Auswahlempfehlungen

3.1 technologische Fortschritte

-

Nano-strukturierte Schmierschichten : Beschichtungen, die mit Wolframdisulfid (WS₂) verbessert wurden, erreichten die Reibungskoeffizienten von nur 0,02 in Metallerz -Quetschanwendungen.

-

Lastanpassungslager : Eine kanadische Entwicklung führte Materialien ein, die auf thermische Veränderungen reagieren, indem sie die Steifheit unter Auswirkungen erhöht und den strukturellen Schutz verbessert.

3.2 Überlegungen zur praktischen Auswahl

-

Geben Sie den Lagern, die auf ISO 4378 getestet wurden, für Schiebflächen und MT/T 593 für die Einhaltung der Bergbau -Sicherheit vor.

-

Wählen Sie aufgrund von Betriebsumgebungen Lager mit internen Räumungen aus, die 15 bis 20% größer sind als die in Standardausrüstung, um Staub und Wärmeausdehnung aufzunehmen.

-

Anfragen Sie Testdokumentation von Lieferanten, die Erzabrieb, Luftfeuchtigkeitszyklus und verlängerte saure Exposition umfassen (z. B. 1.000 Stunden in korrosiven Medien und 5 Millionen Lastzyklen).

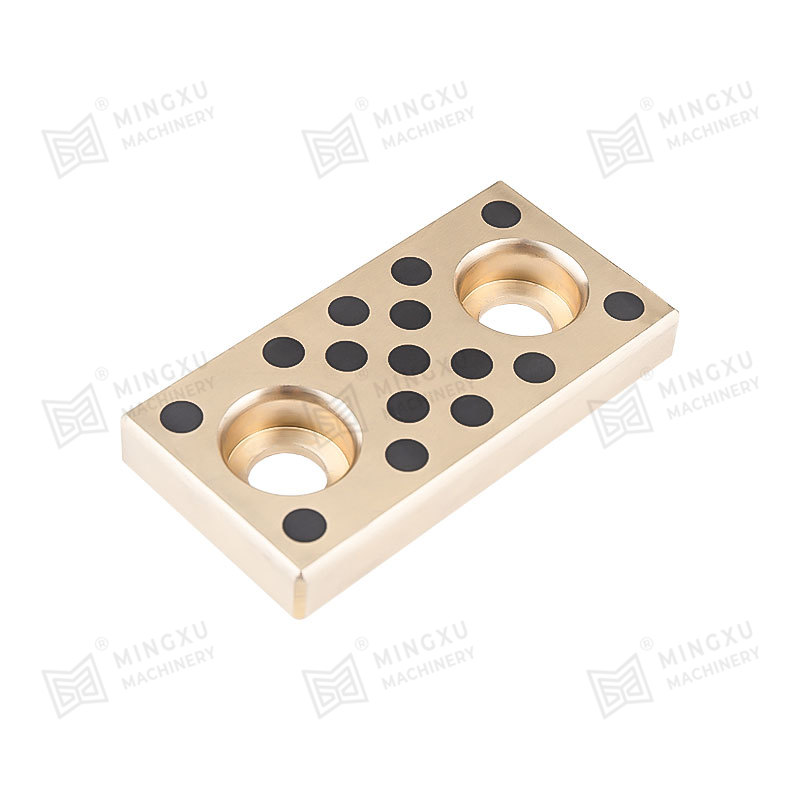

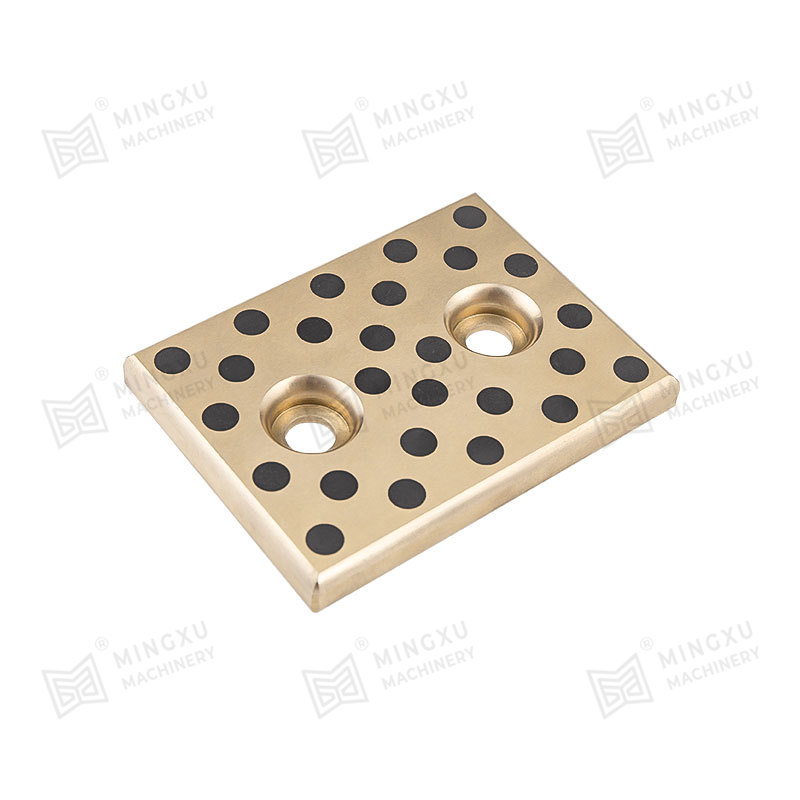

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. ist seit mehr als zehn Jahren mit der Entwicklung und Produktion von selbststrengenden Lagern beteiligt, wobei die Anträge auf Bergbaugeräte kontinuierlich untersucht wurden.

Für technische Konsultationen und Beschaffungsanfragen wenden Sie sich an: [email protected] .

Kontaktiere uns