Solid-lubricating bearings are engineered to operate without the need for continuous external lubrication, making them ideal for demanding automotive and aerospace environments. By embedding solid lubricants directly into the bearing material, these components reduce maintenance requirements, resist wear, and perform reliably under extreme temperatures, heavy loads, and harsh environmental conditions. Their unique properties make them essential in applications where traditional bearings may fail or require frequent servicing.

Advantages of Solid-Lubricating Bearings in Automotive Applications

In the automotive industry, solid-lubricating bearings provide numerous performance and maintenance benefits. Their ability to operate without added grease or oil reduces the risk of contamination and simplifies assembly and service intervals. These bearings also contribute to quieter operation, improved fuel efficiency, and longer component lifespan.

Engine and Transmission Components

Solid-lubricating bearings are widely used in engine and transmission systems where high temperatures, heavy loads, and limited lubrication access are common. Components such as rocker arms, timing belt tensioners, and cam followers benefit from the self-lubricating properties, ensuring smooth operation and minimizing wear over time.

Suspension and Steering Systems

In suspension and steering systems, solid-lubricating bearings are used in control arms, bushings, and stabilizer links. Their self-lubricating design reduces friction, enhances response, and maintains performance under varying temperatures and road conditions. This also eliminates the need for periodic greasing, reducing maintenance costs.

Applications in Aerospace Engineering

Aerospace applications demand bearings that can perform under extreme loads, temperature fluctuations, and high-altitude conditions. Solid-lubricating bearings meet these requirements by offering high wear resistance, low friction, and the ability to function without conventional lubrication, which is crucial for flight safety and reliability.

Landing Gear and Actuation Systems

Solid-lubricating bearings are used in aircraft landing gear, actuators, and control mechanisms. They ensure reliable operation during critical phases of flight, withstand heavy dynamic loads, and maintain consistent performance in extreme temperatures. Their self-lubricating properties also prevent contamination and reduce maintenance downtime between flights.

Control Surfaces and Wing Mechanisms

Aircraft control surfaces, including ailerons, flaps, and rudders, rely on solid-lubricating bearings for smooth articulation. These bearings handle high-frequency motion, resist corrosion, and operate in both sub-zero and elevated temperatures, ensuring precise maneuverability and reliability throughout the aircraft's lifespan.

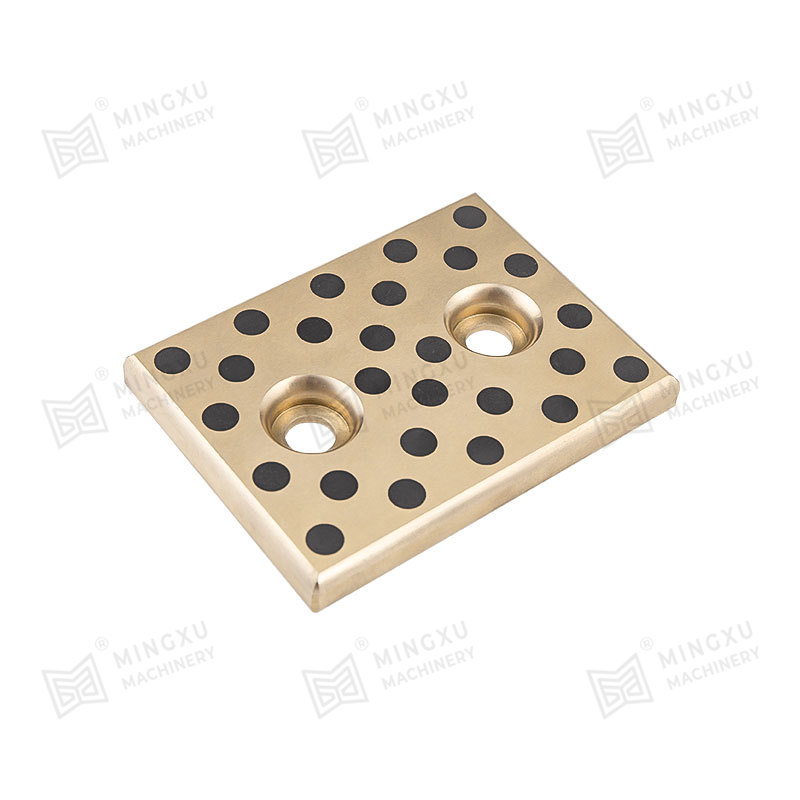

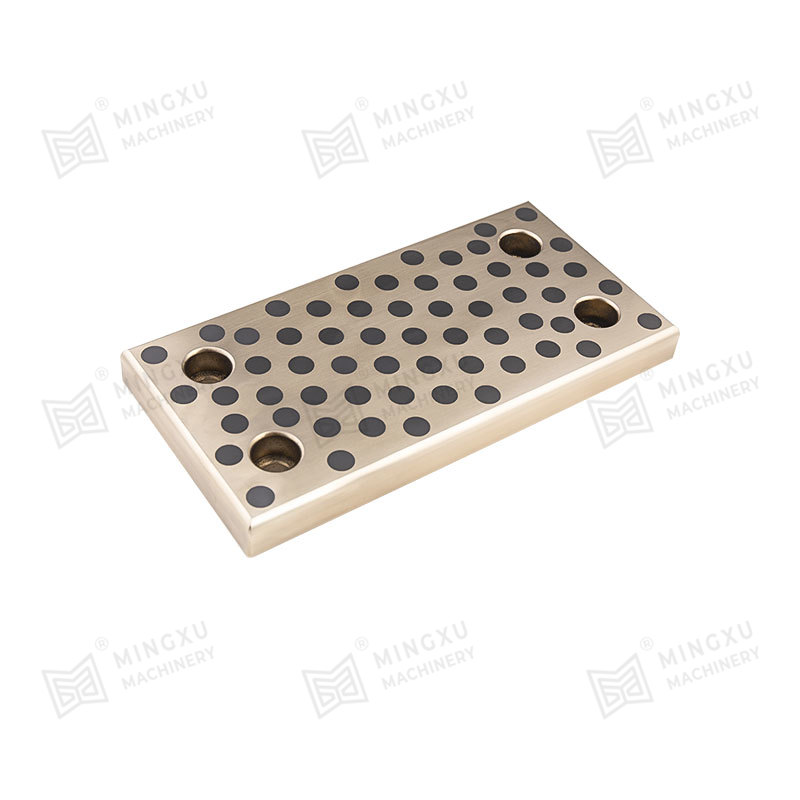

Types of Solid-Lubricating Bearings Used in Automotive and Aerospace Applications

Different bearing materials and designs are used depending on load, speed, temperature, and environmental conditions. The following table summarizes common types and their typical applications:

| Bearing Type |

Material |

Key Features |

Typical Applications |

| Polymer Bearings |

PTFE or composite polymers |

Self-lubricating, low friction, corrosion-resistant |

Bushings, control arms, suspension joints |

| Metal-Polymer Bearings |

Steel or bronze with embedded solid lubricant |

High load capacity, durable, temperature-resistant |

Landing gear, actuators, engine components |

| Graphite-Embedded Bearings |

Bronze or steel with graphite lubricant |

High temperature, dry operation, wear-resistant |

Wing hinges, control linkages, high-temperature zones |

Best Practices for Implementation

Proper selection, installation, and maintenance of solid-lubricating bearings are critical to maximize their benefits in automotive and aerospace applications. Consider the following practices:

- Match bearing material and design to load, speed, and temperature requirements

- Ensure precise alignment and secure mounting to prevent uneven wear

- Inspect bearings periodically for surface wear, contamination, or deformation

- Use solid-lubricating bearings in areas where conventional lubrication is impractical

- Plan for material compatibility with surrounding components to avoid corrosion or abrasion

Conclusion

Solid-lubricating bearings are essential in modern automotive and aerospace engineering, providing reliable performance in extreme conditions while reducing maintenance needs. Their self-lubricating properties, durability, and ability to operate under heavy loads and temperature fluctuations make them ideal for engines, suspension systems, landing gear, and control surfaces. Incorporating these bearings enhances equipment lifespan, operational efficiency, and safety, making them a crucial component in advanced engineering projects.

Kontaktiere uns