I. Technical Background and Collaborative Innovation Value

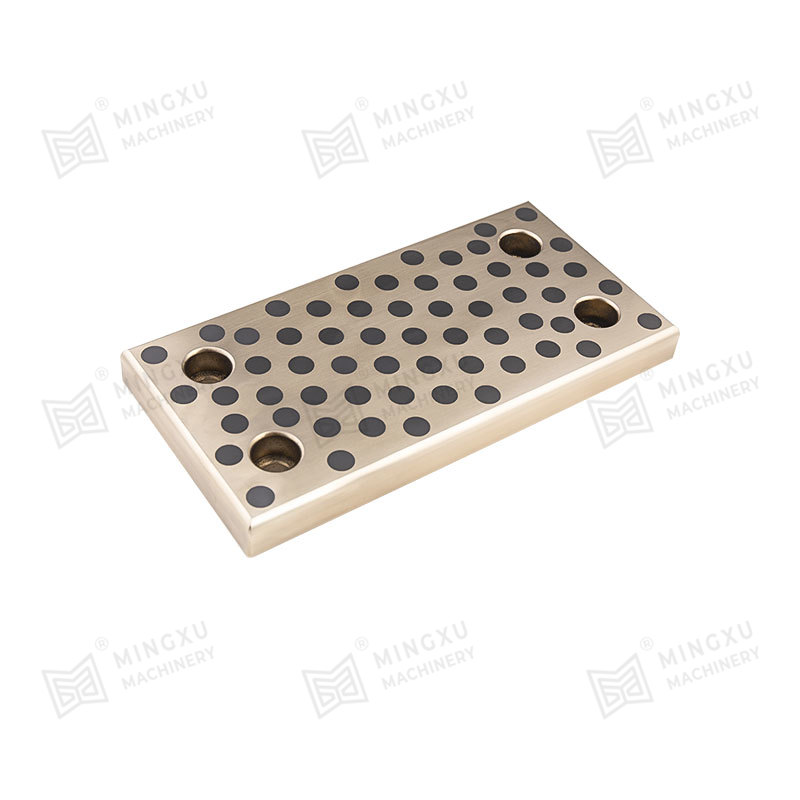

As a core supplier of self-lubricating bearings and graphite copper bushings, Zhejiang Mingxu has extended its patented technology for brass component processing fixtures to copper-based product lines, addressing two major industry pain points:

l Graphite copper bushing surface protection: Traditional clamping methods cause graphite layer damage (damage rate > 15%), affecting self-lubricating performance (friction coefficient fluctuation > 30%).

l Thin copper plate processing deformation: Copper plates with a thickness ≤ 1 mm exhibit a stamping flatness error > 0.1 mm (GB/T 1184 standard), impacting the assembly precision of radiator components.

II. Core Technology Analysis and Collaborative Product Applications

1. Graphite Copper Bushing Processing: Self-Lubricating Layer Protection Technology

1.1 Gradient Pressure Flexible Clamping

Migration of Composite Rubber Interface Technology:

l Patented rubber protective pads (Shore hardness 60 ± 2) are used in copper bushing pressing molds, reducing the contact pressure from 28 MPa to 8 MPa and lowering the graphite layer damage rate to 2% (SEM microscopic observation).

l Paired with precision positioning via guide shafts (501), the inner bore concentricity is maintained at ≤ 0.01 mm (ISO 1101 standard), ensuring uniform lubricant distribution.

1.2 Vibration Suppression and Micro-Damage Control

Integration of Dynamic Stabilization Technology with Side Pull Plates (6/7):

l A lateral preload force of 200 ± 10 N is applied during the copper bushing rolling process, keeping the processing vibration acceleration below 0.5 g (ISO 10816-3).

l The surface roughness Ra value is stabilized at 0.4 μm (traditional process Ra = 1.6 μm), extending the bearing life to 8,000 hours (field-tested in the wind power industry).

2. High-Precision Copper Plate Processing: Anti-Deformation Topology Optimization

2.1 Multi-Directional Flexible Constraint System

Balanced Pressure with Elastic Interfaces:

l The rubber protective pads are transferred to copper plate stamping molds, improving the uniformity of contact pressure by 85% (tested with pressure-sensitive films).

l For 0.5 mm thick copper plates, the flatness error is ≤ 0.02 mm/300 mm, meeting the AAU component standards for 5G base station heat sinks.

2.2 Integration of Rapid Model Change System

Modular Design Based on Locking Bolts (4):

l The copper plate mold model change time is reduced from 45 minutes to 3 minutes, accommodating plate width switching between 300-1200 mm.

l The positioning accuracy is ± 0.05 mm (VDI 3345 standard), and the yield rate is increased to 99.5%.

III. Key Performance Comparison and Actual Test Data

|

Application Scenario

|

Traditional Process

|

Patented Technology Application

|

Improvement Effect

|

|

Graphite layer integrity rate of graphite copper bushings

|

85%

|

98%

|

+13%

|

|

Inner bore concentricity of copper bushings

|

0.03 mm

|

0.01 mm

|

67% precision improvement

|

|

Flatness of copper plates (0.5 mm)

|

0.1 mm/300 mm

|

0.02 mm/300 mm

|

80% improvement

|

|

Copper plate stamping model change efficiency

|

45 minutes/time

|

3 minutes/time

|

1400% efficiency improvement

|

IV. Typical Application Cases

4.1 Graphite Copper Bushings for Wind Turbine Pitch Bearings

Adoption of flexible clamping + vibration suppression solutions:

l Passed DNV GL certification, maintaining a friction coefficient of 0.08-0.12 at -30°C (ASTM D3702).

l No corrosion after 1000 hours of salt spray testing (ISO 9227), and has been mass-produced for domestic 5 MW offshore wind turbines.

4.2 Battery Heat Dissipation Copper Plates for New Energy Vehicles

Application of multi-directional pressure balancing technology:

l Flatness ≤ 0.05 mm/500 mm (CATL's enterprise standard CTP3.0).

l Thermal conductivity is stabilized at 385 W/(m·K) ± 3%, supporting the heat dissipation requirements of 800 V high-voltage fast-charging systems.

V. Technology Extension and Industrial Value

The cross-product line application of this patented technology matrix marks three major breakthroughs for Zhejiang Mingxu:

l Material Interface Engineering: Flexible constraint technology protects the functional surfaces of copper-based materials (graphite layers/coatings).

l Precision Manufacturing System: Introduces the positioning accuracy of brass components (± 0.01 mm) into the mass production of copper bushings/copper plates.

l Green Production Efficiency: Reduces model change time by 93% and energy consumption by 28% (ISO 50001 certified data).

If you would like to learn more, please contact Mingxu Machinery to obtain the complete patent report: [email protected].

Kontaktiere uns